In late 2018 Norman R. Wright and Sons were invited to tender for the construction of one of the most extraordinary timber staircases ever designed. The staircase was to be the centrepiece of the Australian flagship store of a global fashion house who already had form for delivering challenging and eye-catching timber features for their Paris and Moscow flagship stores. The brief for Sydney, it seemed, was to push the boundaries even further.

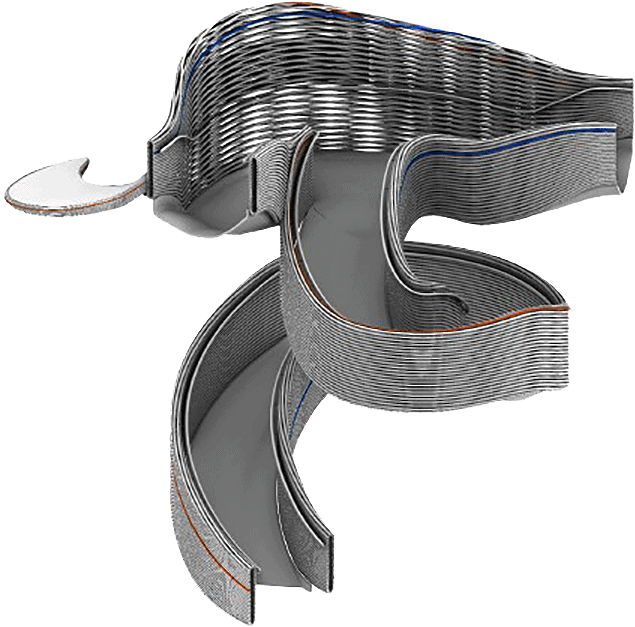

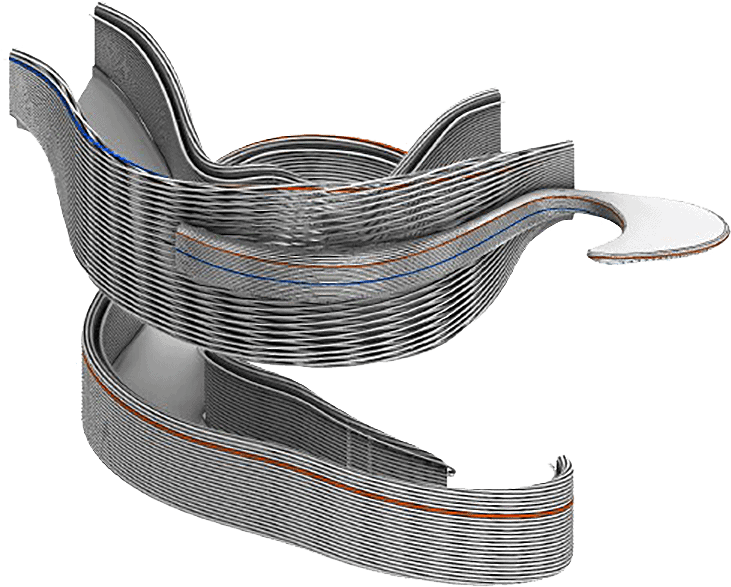

The design concept called for a spiralling and branching double layer of timber strappings (or laths), alternately oriented and twisting to give a woven effect. The overall shape evokes the twisted buttresses of an ancient banyan tree emerging from the ground.

The central structure was to be of steel construction (by others), with the steel balustrading to be “wrapped” in the timber laths, and the underside of the steel treads to be concealed with a soffit of alabaster white continuously transitioning surfaces.

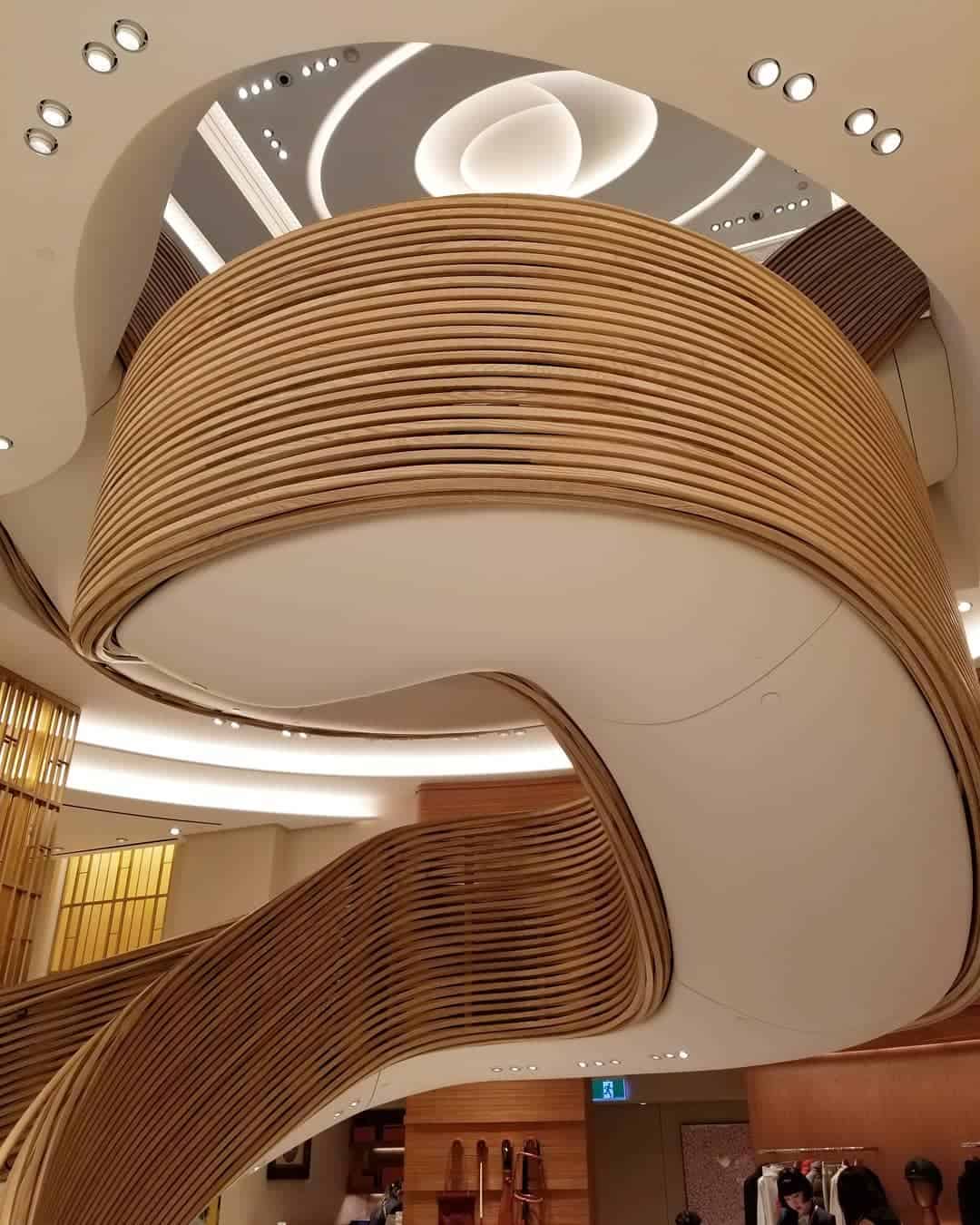

The finished store (Photo Felix Forest)

Key features of the design included :

The architects and construction contractor recognised early on that the organic design was not a job for regular shopfitters and joiners and that local boatbuilders familiar with steam-bending timbers and lofting stylised surfaces might be chance, and if not, the Europeans would need to be flown in.

The fashion house, family run for generations and noted for their exquisite craftsmanship, saw something of the same in Norman R. Wright and Sons, and to our delight, and significant apprehension, we were trusted to turn their concept into a reality.

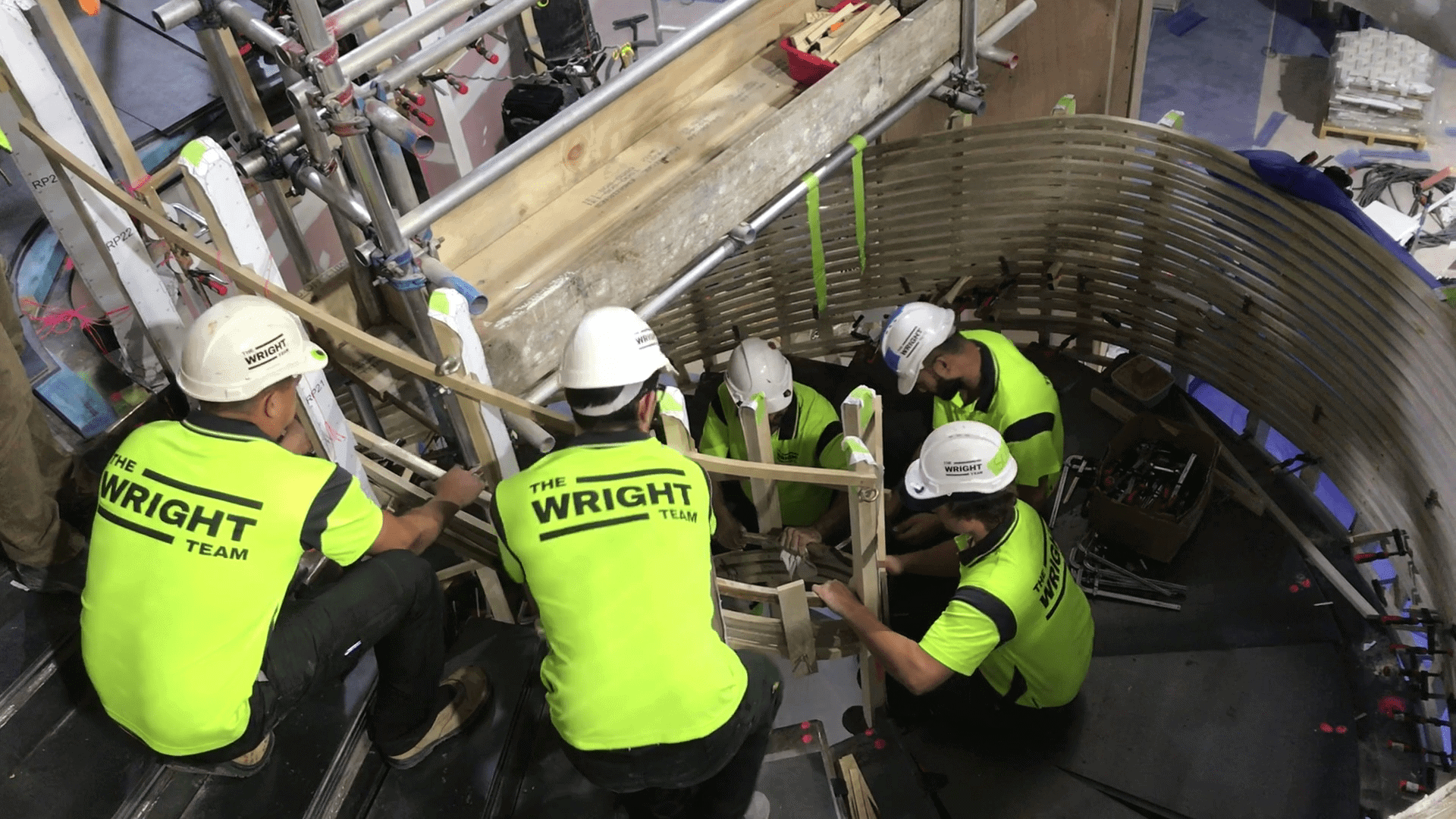

With the sheer scale and technical challenge of the project, it was clear we would need help, and the obvious choice was long time collaborators Wright Marine led by Shannon Wright (no relation). “The Wright Team” was born, eventually setting up digs in Sydney with a team of up to 8 practically living on site for a 9 month install.

To add to the challenge, the staircase was to be installed in the center of a well known heritage building –Sydney Trust Building (cnr King and Castlereagh Streets) – which afforded little in the way of access or areas for workshops.

(Photo Felix Forest)

Prior to install though, we needed to finalise the designand determine exactly how this staircase could be built. (Some early trials gave us hope, but by no means did we have all the answers yet!)

Laths:

The solid timber laths spiral up from the ground floor to the top floor in continuous runs of up to 22m and passing through numerous bends as tight as 180mm. A lath that starts at the ground floor on the inside of the balustrade, may during this journey, eventually rise up and twist over the top of the balustrading to finish on the outside of the balustrade. The tightest section of the staircase was mocked up. Formers, jigs and steam boxes were built. A selection of timbers and bending processes were trialled along with a number of different jointing systems.

The prototyping phase resulted in the selection of planation grown American White Ash for the timber (hand selected/graded), a system of soaking and steaming the timber, and the development of a propriety scarfing and jointing system.

Early lath steam bending trials and resulting prototype section.

Whilst we were relieved to develop what appeared to be a successful process, it was quickly realised that the entire lath structure would have to be constructed on-site from scratch with steam bending and scarfing taking place in-situ. There would be no factory-efficient, modular construction.

Soffits:

The soffits had to be lightweight, removable in sections so as to provide access to electrical and fire services, be perfectly smooth and provide a consistent tight gap to the timber balustrading. We settled on a traditional timber strip planked design sheathed in lightweight glass and faired and painted. With no space on site, these would have to be built remotely at our yard in Brisbane and shipped to site for final assembly.

A soffit prototype.

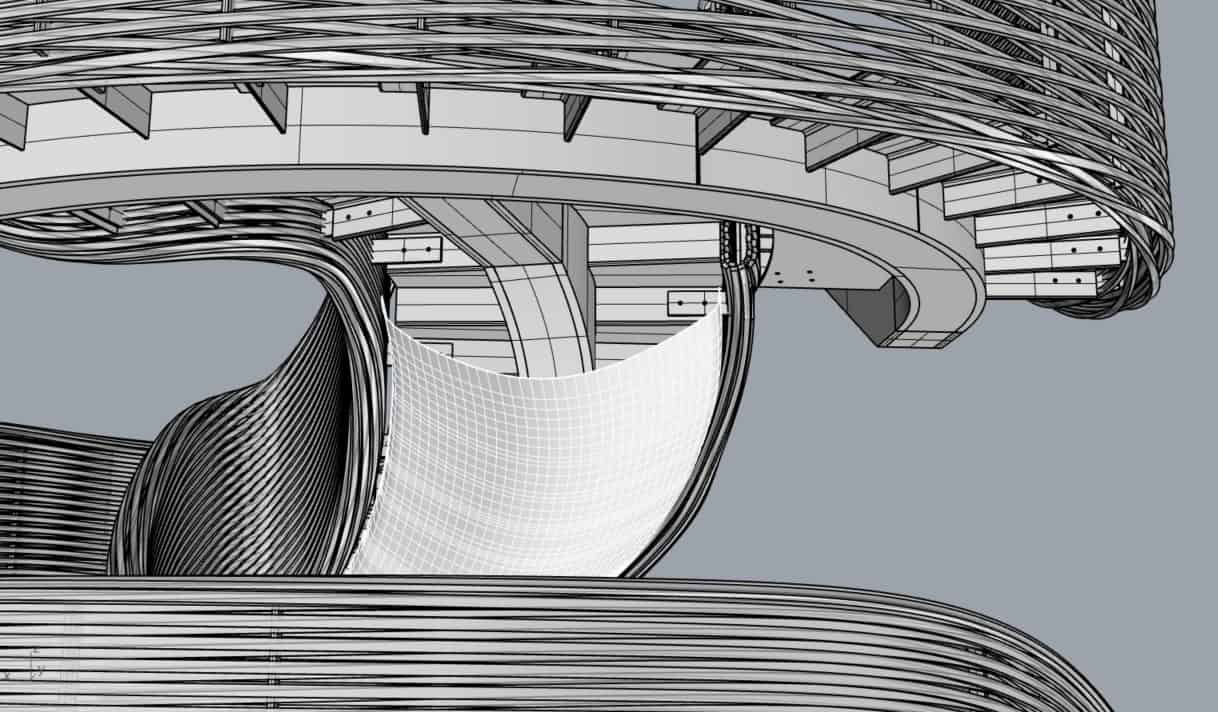

Although construction appeared freeform and utilised traditional handcraft based techniques, the reality was that success depended on everything following a highly rigid plan, dictated by a 3D CAD master model assembly of the whole staircase. Critically, with the laths being constructed on site and the soffits offsite, building to a 3D model would ensure everything came together in a neat fit.

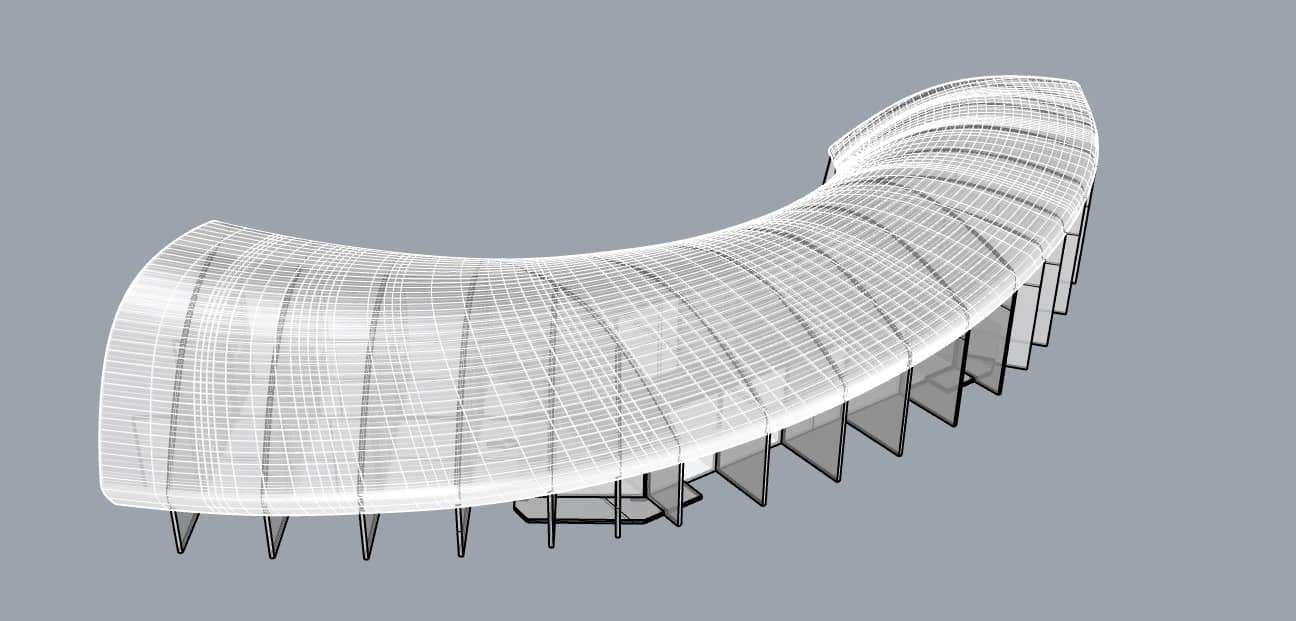

A 3D concept model was provided by the architectural team on which the lath designs were refined and the soffit surfaces were lofted. Importantly, once the steel structure had been installed, a 3D scan of the “as-built” was taken and fed back into the 3D model and the whole virtual assembly refined. This was essential step if we were to have any chance of the soffits fitting.

3D Scan of Steelwork.

Finalised 3D model ready for production (one of the soffits lofted in white).

From the model, jigs and templates where devised to guide the laths along the balustrades, ensuring that the spacing and curvature remained consistent and there was no “crowding” of laths as each lath twisted up and over from one site of the balustrade to the other.

The modelled soffit surfaces were used to digitally cut all the framing for creating the strip planking moulds.

Framing for soffits moulds.

The complexity of the timber balustrading meant production would be an exercise in pure brute handcraft as every single piece length of timber, each between 2m and 3m and cross section of 30x20mm, had to be individually bent and twisted to it’s own unique shape, clamped to the stair structure to “cure” in place, and then eventually be fixed with “secret fixings” and scarfed and glued to the next length.

With over 6,000m of laths to steam bend, a team of up to 8 boatbuilding trades and apprentices worked over a period of 9 months working 6 days a week, and 12hrs (or more!) a day. A temporary workshop was setup within the building that included 3 custom built steam boxes which mostly ran 12hrs a day. As the works were taking place at the geographic centre of the project, and the steel staircase often being used for foot traffic, the Wright Team appeared to be at the very heart of an extraordinary refurbishment project swirling with a myriad of the highest quality tradespeople such as metalsmiths, stonemasons, glaziers, and plasterers.

The preparation for a bend like this is extensive.

100’s of clamps were purchased for the project.

Outer layer of laths being applied.

Meanwhile, the soffits were being produced by a team of boatbuilding trades at our boatyard in Brisbane. The timber stripped planking approach was a wonderful opportunity for many of our apprentices to experience traditional timber boatbuilding techniques. There were more than a few comments though on the weird shapes being produced and plenty of doubtful glances from our boating clients! Each of the soffits where checked for absolute smooth transitions between adjacent soffits using a series of custom jigs and then faired and painted

The soffits were shipped to Sydney on a flat bed semi-trailer and installed onto the underside of the staircase snuggly between the timber clad balustrades.

Strip planking (foam strips used in very tight areas).

Resin coated soffit (was a shame to paint!).

Sheathing in glass.

The installation of the soffits saw the last of the steelwork covered and the beauty of the overall design come together for the first time.

Fitting the first soffit.

Fitting soffits.

Final fitoff of soffits.

We will let the following quotes and pictures speak for the results:

“The first thing you notice when you walk in the door of the new Sydney flagship [store] is not the [high end fashion merchandise]. No. The thing you notice is the enormous staircase, swathed in sweeping, stacked parallel columns of ash wood, each piece curving around the custom-made winding balustrade. It’s exquisite.” Australian Financial Review, June 2020.

“At the heart of the store, however, is its star: a spectacular meandering staircase in marble and ash wood both brilliant and unique. Designed by the Parisian architecture agency, the extraordinary staircase was fashioned by steam and made by hand, and is arguably the pièce de résistance in the store’s interior. With its double revolution or helix and a half, it creates a pathway like no other to descend down to the lower ground floor. The wild balustrading of the wood used in this mighty structure recalls the impressive aerial roots of the great Australian Banyan tree and celebrates the spirit of the surrounding nature, an homage to the natural environment that helps define life in Sydney and which has been embraced fully by the French maison.” Grazia, June 2020

“Shoppers are then invited to descend to the lower ground floor by way of the show-stopping marble and ash wood staircase — a staircase with as much attention to design detail as a piece from the brand surrounding it.” Vogue Magazine, June 2020.

“I am so glad it was not made by a usual carpenter but by a boat builder. And you know, I think it would have been quite a fun project for them. They have the knowledge to do it and the ability.” Project’s Lead Architect.

The finished store (Photo Felix Forest)

Credits

Facts